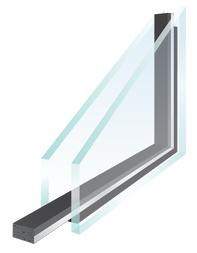

SLIM DOUBLE GLAZED UNITS TO MATCH ORIGINAL SINGLE GLAZED WINDOWS IN TRADITIONAL & HISTORIC BUILDINGS

|

Heritage Sealed Units ® is an elegant 21st century solution to an age-old problem; high performance with outstanding aesthetics.

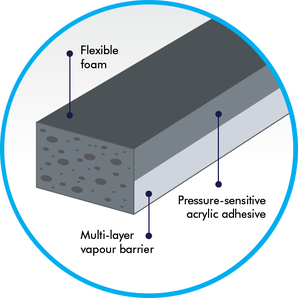

JCL Glass offers the latest low sight line Heritage Sealed Units ® (slim, double glazed units) to replicate and enhance original single glazed windows in traditional and historic buildings. Using a high performance warm edge spacer system, Heritage Sealed Units ® are designed specially to meet the needs of the timber window restoration and replication sectors where the overriding criterion is authenticity. The flexible foam spacer is desiccant filled with pre-applied adhesive and multi-layer vapour barrier backing, this simplifies the slim sealed unit manufacturing process yet enables low sight lines and narrow unit cavities. The combination with hot melt secondary sealant provides excellent durability. |

* Spacer bar is only 3mm in depth enabling low sight lines

|

TALK TO THE EXPerTS

For all Heritage Sealed Units® requirements.

get in touch with JCL Glass today.

get in touch with JCL Glass today.

OUR STANDARDS

|

At JCL Glass, our commitment to quality is at the heart of everything we do. Our Heritage Sealed Units ® (slim double glazed units) undergo rigorous testing to ensure they conform to BS EN 1279, a key industry standard for insulating glass units.

We're not content with meeting standards; we're dedicated to exceeding them. Our partnership with CEN Solutions, industry consultancy leaders, allows us to continuously improve our slim double glazed units. When you choose Heritage Sealed Units ® from JCL Glass, you're selecting exceptional quality produced by a team with years of expertise and knowledge of glass processing. |

heritage sealed units® AVAILABLE

FOR NATIONWIDE DELIVERY

The BEnefits

HERITAGE INSTALLATION GUIDE

All the information for installing Heritage Sealed Units®

at the click of a button.

at the click of a button.